You put them on

and forget

about them

You put them on

and forget about them

webee is designed and produced in Italy where technology meets craftsmanship and tradition. The production process for each pair of glasses entails 42 production stages with high manual skill to guarantee robustness, comfort, tactile pleasure and aesthetic design.

The construction details of webee are based on traditional eyewear manufacturing that has today been replaced by industrial mass production processes. The aim of all the webee construction specifications is to improve the comfort and strength of the frame while also enhancing its aesthetic value. Beauty and technology enhance the lightness of the material.

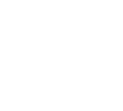

Rounded milled nose bridge

The nose bridge is rounded outwards and milled internally for maximum comfort on the nose.

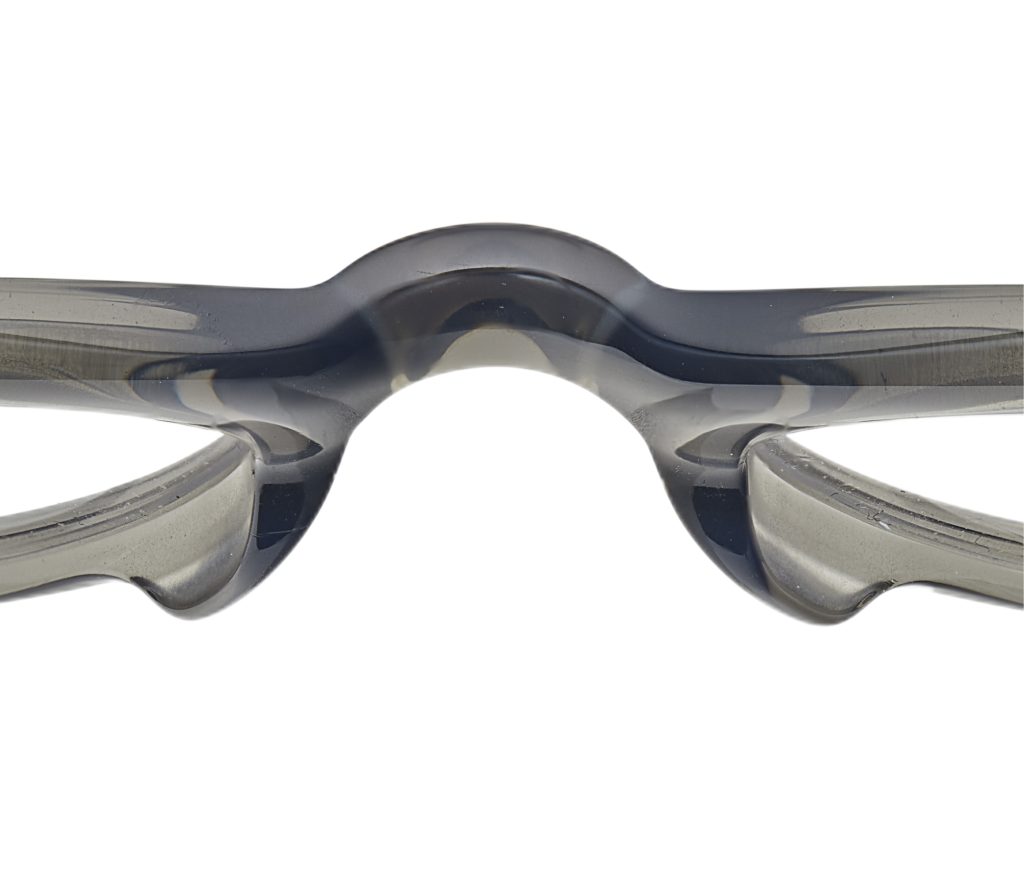

45° join

The 45° join between the front-piece and the temple makes for a surface that is smoother and more even to the touch as well as being invisible.

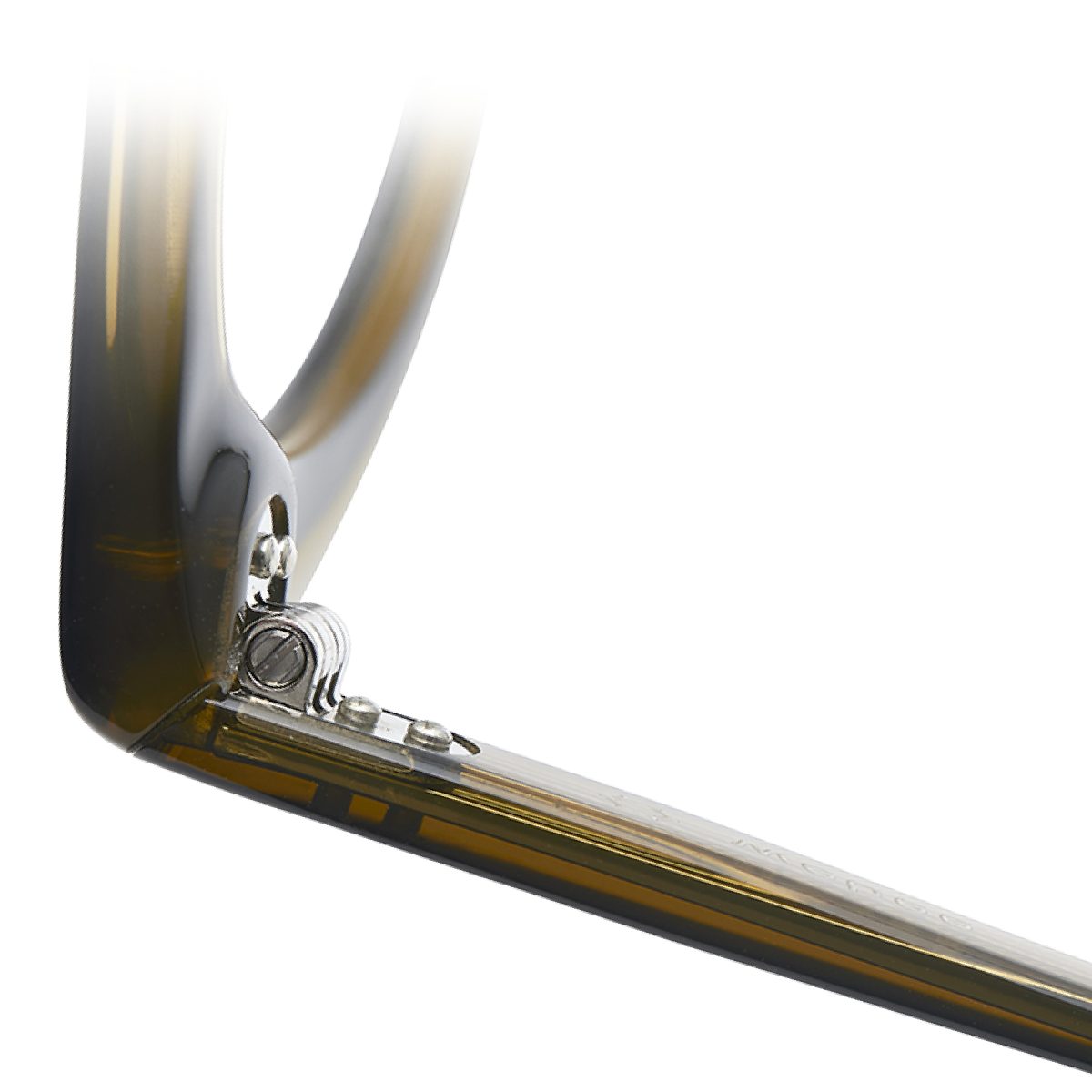

Milled hinge mount

Milling the hinge mount increases the solidity of the frame and enhances its aesthetics.

Lapped rivets

Manually inserted rivets are polished to make their surface smooth. In addition to being decorative, they increase the solidity and strength of the frame.

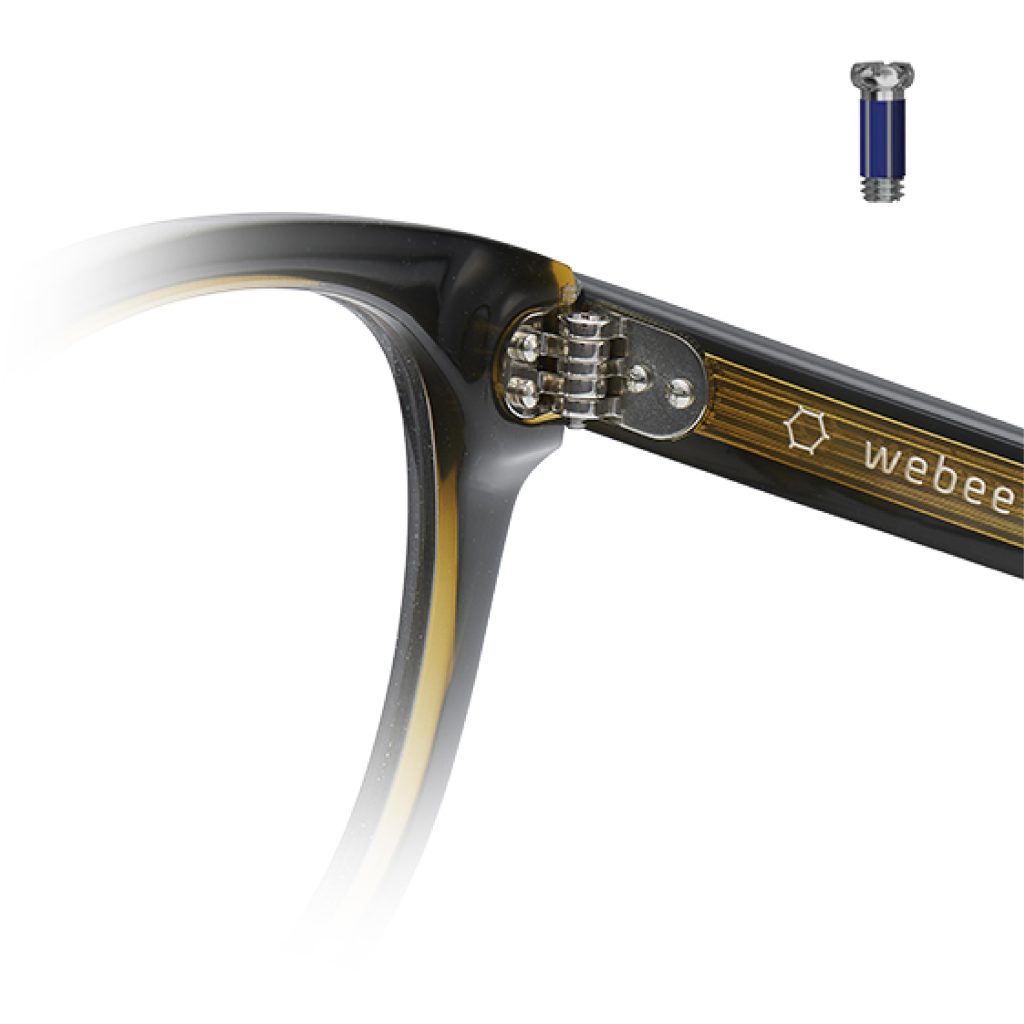

Polyamide coated screw

Coating the screw with polyamide maintains regular friction and prevents the screw from loosening.

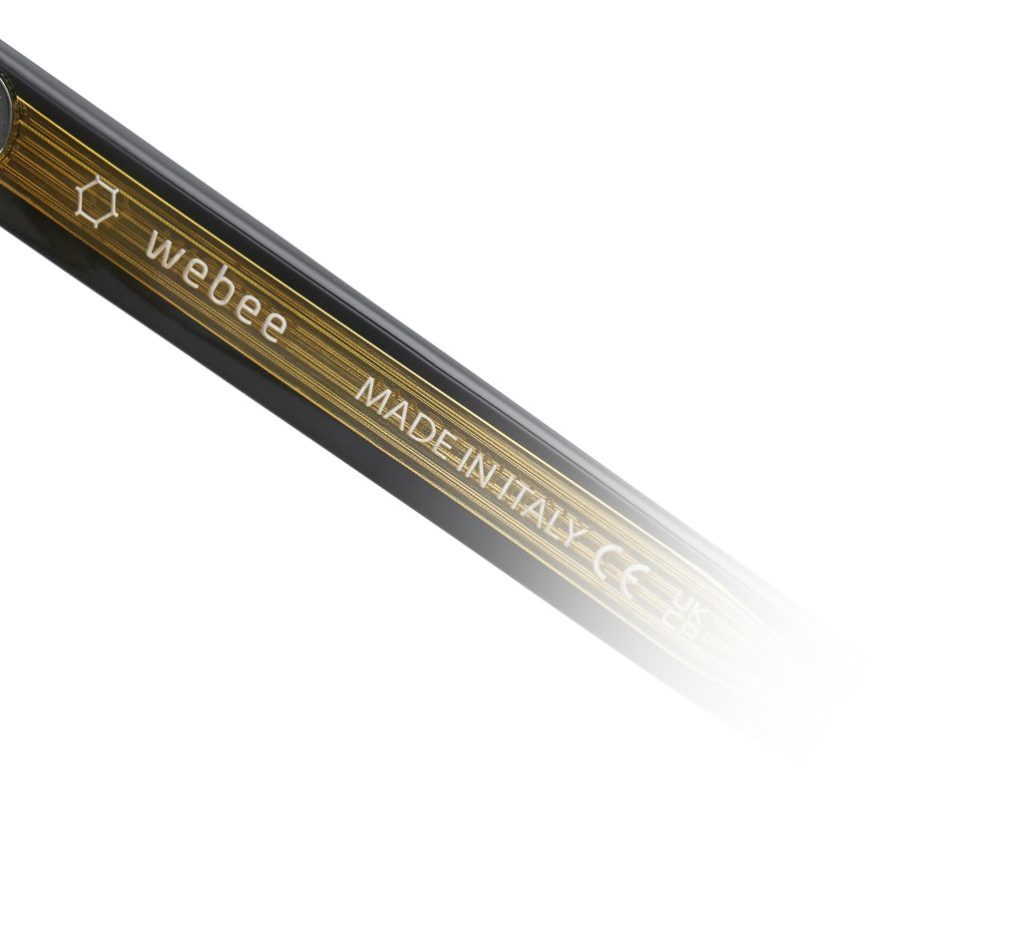

Copper alloy core and laser-engraved logo

The temple core is in copper alloy to increase flexibility and comfort. It is decorated on both sides for aesthetic reasons. The logo is laser-engraved to avoid using lacquers, paints or varnishes and to make it inconspicuous.

Ridged rounded temple end

Rounded to increase comfort on contact and ridged for greater wearing stability to prevent slipping.

Laser-engraved writing

The description written on the inside of the temples is laser-engraved to guarantee aesthetics and resistance to wear and tear.

How webee manufactures

Watch the video